Wood-plastic composites are a sustainable solution that makes use of organic material with virgin, recycled or renewable plastics.

Manufacturers have been combining petroleum-based plastics with organic material since the very early days of plastics manufacturing.

Rice hulls, walnut shells and ground oyster shells were all used as affordable fillers that enabled manufacturers to cut costs while maintaining quality.

Eventually, inorganic materials, such as chalk and calcium carbonate were substituted with the goal of making a more affordable plastic.

But there were downsides to using inorganic fillers.

As more and more were added to the plastic, the finished product lost impact strength and became too rigid.

The focus began to shift from using inorganic fillers to again using organic material to supplement plastic production.

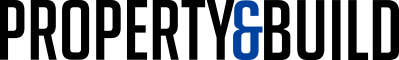

Using sawdust and other waste materials from sawmills proved to be an affordable and sustainable tactic for making a plastic that was not only of high quality, but also visually appealing to consumers.

Wood-plastic composites feature the benefit of reduced melting temperature, resulting in lower energy costs for producers, and further reducing the product’s environmental impact.

Wood-plastic composites may often be used with existing tooling. For manufacturers, this eliminates an investment that would need to be recouped before cost savings could be realised.

And since wood does not need to be treated when making wood-plastic composites, wood scrap could be used immediately after being reclaimed, without the addition of potentially harmful chemicals.

Today, the classic look of wood can be effectively imitated, but with the added benefits of improved strength, durability, and weatherability.

The promise of wood-plastic composites

Wood and plastic each bring their own strengths to a composite material.

Plastic enhances the strength and durability of the wood, and wood lends a look and feel to plastic that had always been lacking in older formulations.

For example, in decking made from wood-plastic composites, the circumstances call for a tough material that can withstand assault from the elements.

By experimenting with the type and ratio of plastics blended with wood, different visual and tactile effects can be achieved.

Different formulations are capable of yielding a variety of colours, more fibrous or smoother textures, more flexibility or more rigidity.

These aesthetic qualities are achieved through variations in the type of wood fibre and particle size, as well as the type of recycled, reclaimed or virgin plastic used.

An automotive manufacturer might seek to reproduce the warm, classic feel of wood in a car interior with a formulation that is both smooth to the touch and durable enough to maintain a premium brand image.

A furniture manufacturer might recreate the classic craftsmanship of wood furniture, but do so in a sustainable fashion.

Wood-plastic composites are compatible with most plastic processing tooling and are far more efficient to produce compared to traditional woodworking.

Most machinery capable of moulding conventional plastics can also mould wood-plastic composites.

Colours can be embedded in the plastic itself, removing the need to paint finished products.

This eliminates toxicity concerns that may otherwise come with toys designed for infants or pets.

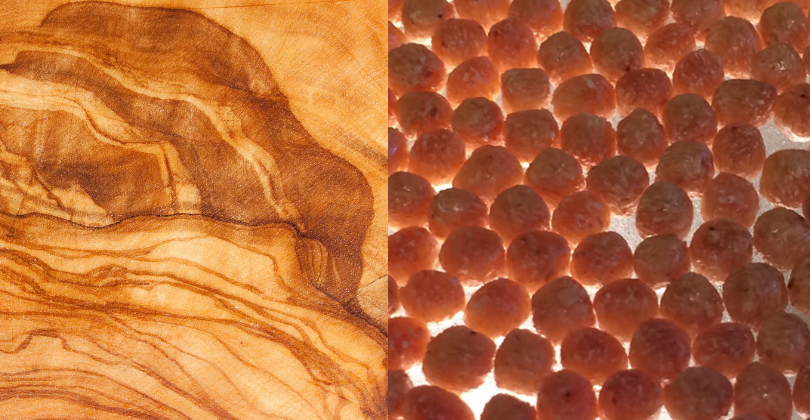

Recently, a large toy manufacturer investigated prospects for improving their margins on a popular classic toy. They selected a wood-plastic composite alternative.

The company began injection moulding a wood-plastic composite instead of shaping wooden pieces, bypassing one of the most expensive steps in their manufacturing process.

Also, because colour could be added during the moulding process, the parts did not need to be painted. This eliminated the concerns of peeling or chipping paint.

New uses for wood-based composites are constantly being realized. From car speakers and interiors to home furniture and kitchen accessories, these hybrid materials are providing sustainability, longevity and cost savings in new consumer sectors.

About the contributor

Green Dot specialises in formulating wood-plastic composites pellets and works closely with clients to achieve the desired aesthetic and material ratios needed to yield success. http://www.greendotpure.com/